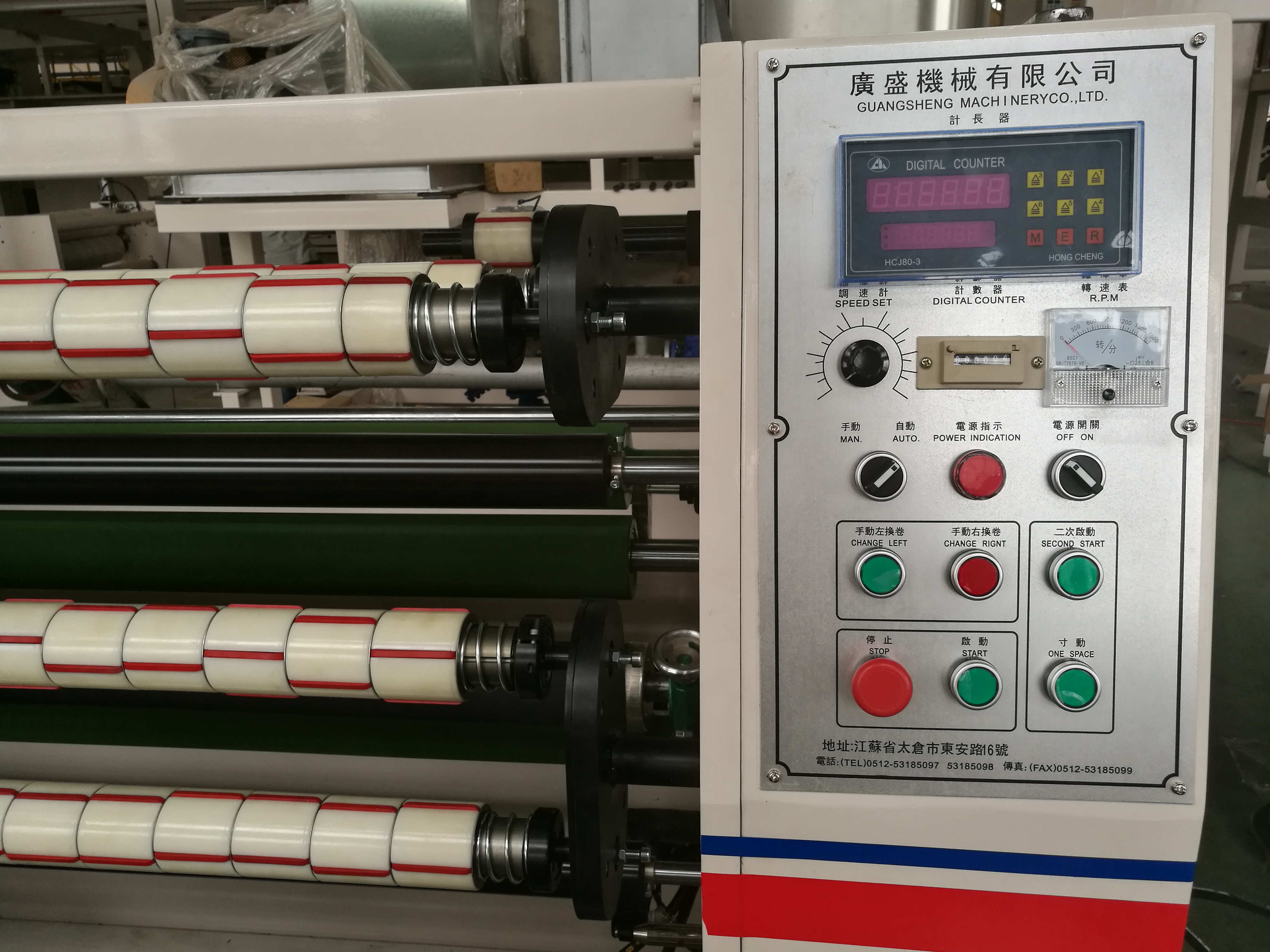

Soundproof packing adhesive tape slitting machine

General technical parameters(customized):

| Width | 1300mm/1600mm/1800mm/2000mm |

| Max. unwinding diameter | 700mm |

| Max. rewinding diameter | 150mm |

| Slitting width: | 18-1800mm |

| Slitting tools: | razor blade |

| Paper core | 76.2mm |

| Machine speed | 150m/min |

| Unwinding shaft | 3’ air shaft |

| Unwinding brake | 10 KG Pneumatic brake |

| Rewinding shafts | Aluminum shaft with bushes |

| HMI | Weinview |

| Drive motor | AC 7.5HP motor with inverter(Taiwan+Mitsubishi) |

| Soundproof device: | Apply 2 air cylinder auto control open and close |

| Up-down load jumbo roll | Apply hydraulic pressure station driven by 3HP fluid pump |

| Power use | 380V 50Hz 3Phrase |

Application:

This is one set of Soundproof packing adhesive tape slitting machine mainly for making packing adhesive tapes,the minimum slitting width can be 18mm,it applies hydraulic pressure station to support up-down load jumbo rolls.Also this slitting machine with a soundproof cover. A soundproof cover function is added to the tape jumbo roll based on the original equipment configuration, which can effectively reduce the noise caused by unwinding during the production process. At the same time, the hydraulic station is used to achieve lifting loading, which is convenient, fast and saves manpower.

Features:

This is a tape slitting machine with a soundproof cover. A soundproof cover function is added to the tape mother roll based on the original equipment configuration, which can effectively reduce the noise caused by unwinding during the production process. At the same time, the hydraulic station is used to achieve lifting loading, which is convenient, fast and saves manpower.

It has several features:

A) A soundproof cover function, which can effectively reduce the noise caused by unwinding during the production process

B) Apply Mitsubishi control system which can ensure stability of machine operation,trouble-free.

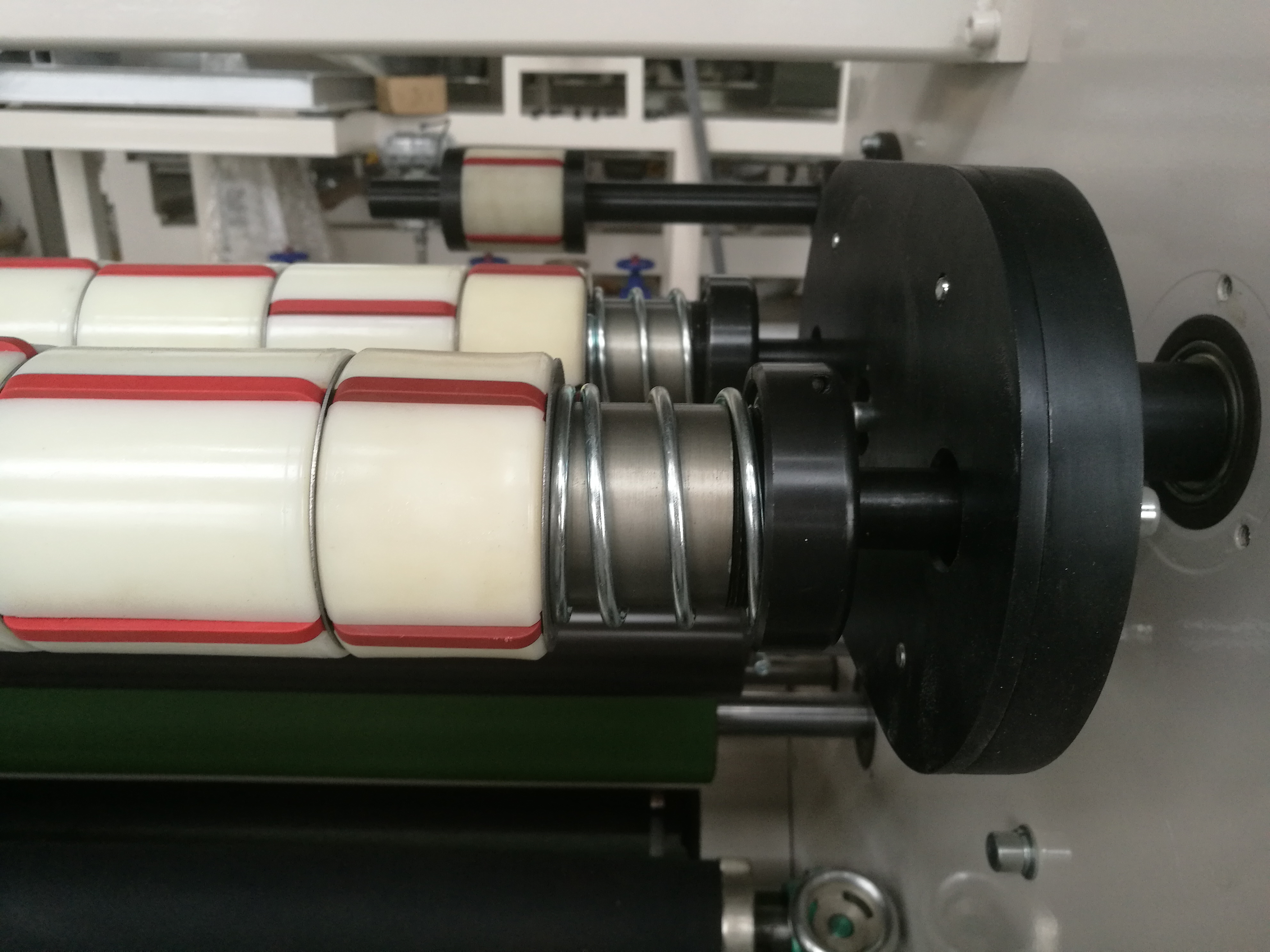

C) Bubble free device applies 2 pieces rubble pressing rollers which controlled by air cylinders.

D) Apply hydraulic pressure station to up-down load jumbo rolls.

E) More simple and easier to operate by HMI.

F) Low cost &high return

G) Unwinding part controlled by Pneumatic brake

H) Apply HMI display data,which is more simple and convenient.