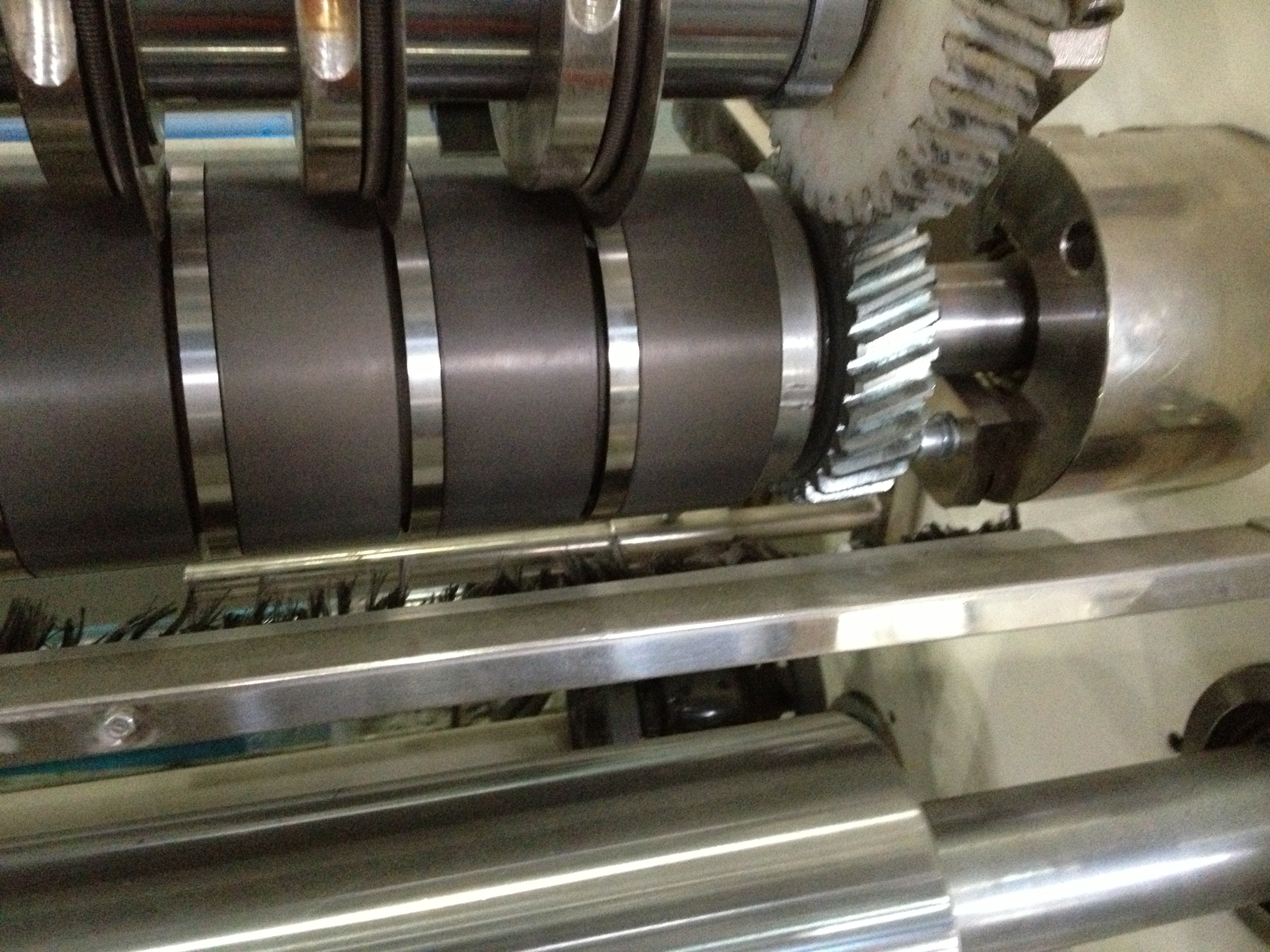

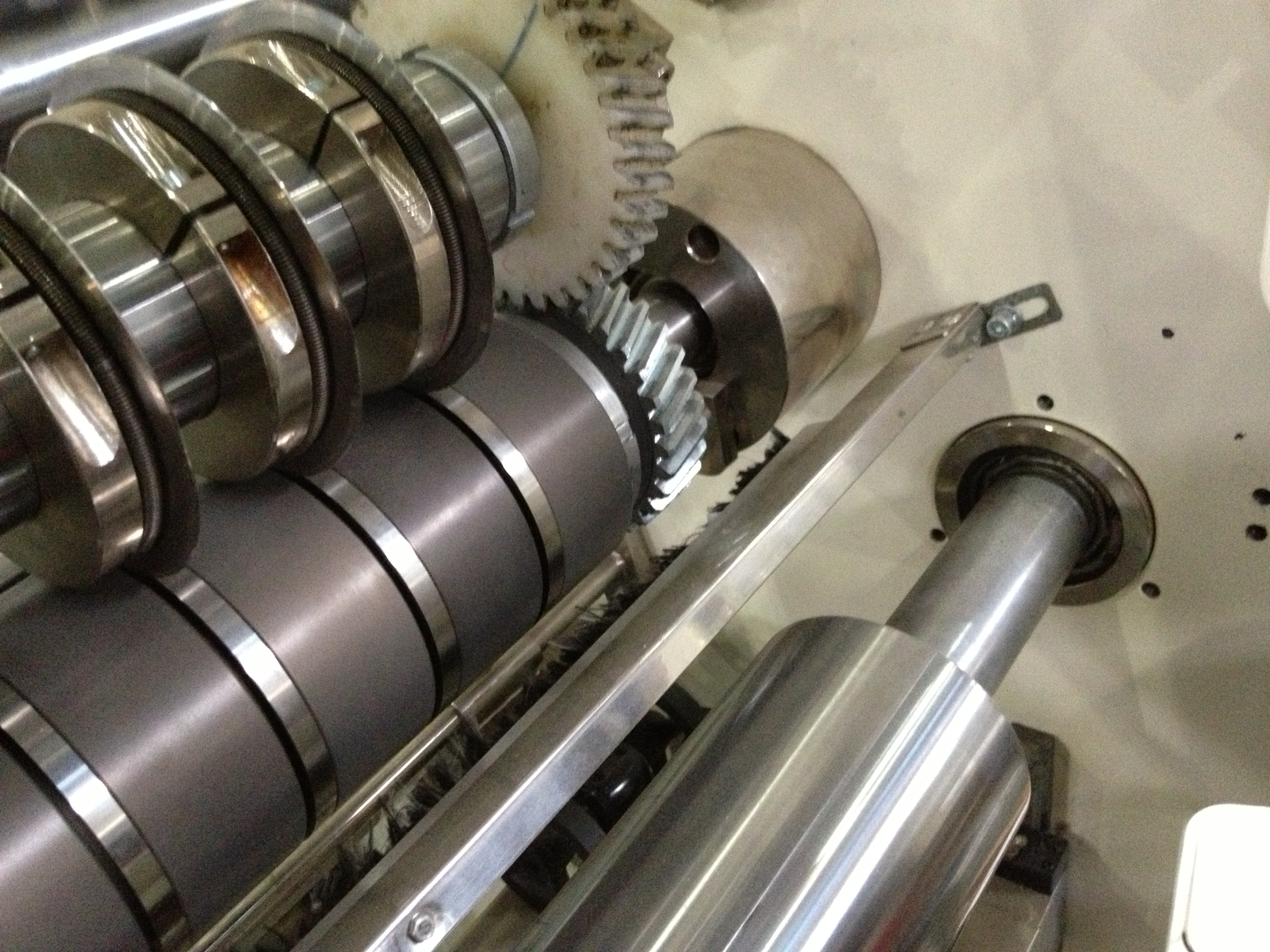

GS205 Kraft paper products slitting and rewinding machine

General technical parameters(customized):

| Width | 1300mm/1600mm |

| Max. unwinding diameter | 1000mm |

| Max. rewinding diameter | 500mm |

| Paper core | 76.2mm |

| Machine speed | 0-150m/min |

| Type: | Apply independent unwinding device and double shaft rewinding |

| Unwinding shaft | 3’ air shaft |

| Rewinding shaft | 2pcs 3’ air shaft |

| Slitting tools: | Customized round blade |

| Rewinding length | Use 3-stage counter |

| Drive motor | 7.5 HP motor with inverter |

| Tension control | 10kgs Magnetic powder clutch |

| Electrical control | PLC (Mitsubishi) |

Application:

This is a multifunctional slitting and rewinding device mainly used for slitting and rewinding paper products, such as kraft paper, label paper, sublimation transfer paper, etc .The whole machine adopts Mitsubishi PLC program control and online correction system to ensure stable operation and prevent material deviation. The slitting tool adopts a customized round blades, with an adjustable blade shaft design, suitable for slitting with different width requirements; Adopting hydraulic station lifting feeding, simple and fast, saving manpower.

Features:

The whole machine adopts Mitsubishi PLC program control and online correction system to ensure stable operation and prevent material deviation. The slitting tool adopts a customized round blades, with an adjustable blade shaft design, suitable for slitting with different width requirements; Adopting hydraulic station lifting feeding, simple and fast, saving manpower.

It has several features:

A) Machine adopts Mitsubishi PLC program control and online correction system

B) Apply hydraulic station lifting feeding, simple and fast, saving manpower.

C) Slitting tool adopts a customized round knife, with an adjustable blade shaft design

D) Apply independent unwinding device,suitable for kinds of different material.

E) Use 3-stage length counter to ensure accurate rewinding length.

F) Auto tension control in unwinding part by magnetic powder clutch.

G) Arch roller can effectively expand material,then remove the wrinkle of material.

H) Knurling roller with teflon treatment,anti-stick when through the material