1600 Biaxially Oriend Polypropylene(BOPP)adhesive packing printing tape/sealing tape/gum tape/scotch tape/transparent tape/stationery tape coating machine

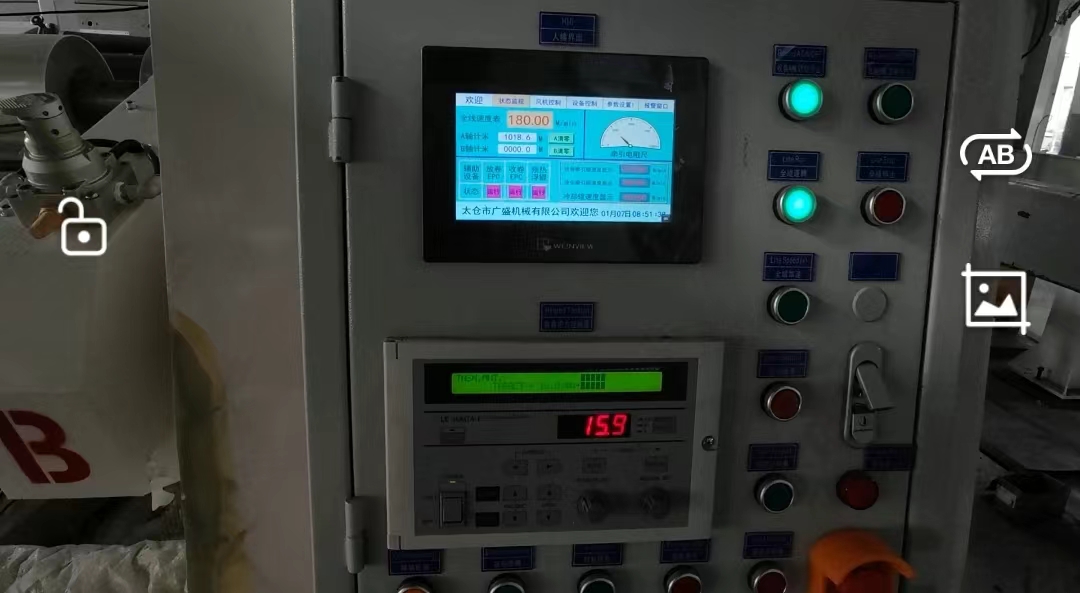

Technical parameters:

| Machine width(mm):(can be customized) | 1600mm |

| Machine speed(m/min): | 0-200m/min |

| Substrate thickness(μm): | 23-60μm |

| Coating thickness(μm): | 12-30μm |

| Coating methods: | Double mayer coating |

| Temperature of oven(℃): | 80-120℃ |

| Heating ways: | By electric,steam,hot oil,hot air |

| Automatic grade: | Automatic/semi-automatic |

| Tension control: | Each section has tension controllers which can ensure the BOPP film running stably,without wrinkle,rewinding orderly.(Mitsubishi,Japanese) |

| Drive type: | By motor(Made by Taiwan ) |

| Voltage: | 380V/400V/420V/440V(Depends) |

| Leading time: | 4 months(100days) |

| Country of origin: | China |

| Brand : | GS |

| Dimensions: | 28/32/36/40/44/56m(L)*2.3m(W)*6.5m(H) (Depends) |

| Weight: | About 42T |

| Certification: | CE certificate |

| Warranty: | At least 1 year |

| After-sale service: | Contact us,anytime,anywhere, response within 24hour |

| Packing&delivery: | Seaworthy packing,loading into containers(40HQ &20GP),big trucks transport to Shanghai port,then load to vessel to destination port. |

Application:

Suitable for making BOPP adhesive packing printing tape/sealing tape/gum tape/scotch tape/transparent tape/stationery tape jumbo rolls.

Features:

This machine is customized as required.

It has several features:

A) Unwinder : the automatic unwinder which can change rolls without stop machine, when a roll of jumbo BOPP film unwinding to be over, the other roll will get in at once, which can greatly save the feeding time thereby improving production efficiency.

B) Coater: apply double mayer bar coater which is easily use, operator can quickly grasp the key point and make good quality bopp jumbo rolls, also its low cost but high cost performance. Besides, the user can change the different thickness of material rather than change the adhesive composition or make adjustment on machine to meet different product requirements.

C) Oven: the customer choose traditional oven type, the oven can open from side door which can observe the inner situation of each section, the oven liner apply stainless steel,each section has 8 pieces anti-stick Teflon rollers which can ensure BOPP film running stably when getting through the oven. Beside,in order to increase its thermal insulation property, 100mm insulation cotton rock be used in each section, which greatly ensure its heat preservation effect of each oven.

D) Tension control: the tension of each section can be controlled separately, which can keep the BOPP film running stable without wrinkle and shrinkage.

E) Rewinder: the automatic rewinder which can change rolls without stop machine, when a roll of jumbo BOPP film unwinding to be over, the other roll will get in at once, which can greatly save the unloading time thereby improving production efficiency.

F) Cooling system: three-rollers type cooling system will greatly improve cooling effect.